smaller engines, the turbine rotor is under severe centrifugal loads.

Consequently, the turbine disk is made of specially alloyed steel,

usually containing large percentages of chromium, nickel, and cobalt.

The turbine rotor assembly is made of two main parts, the disk and

blades.

Nozzle vanes may be either cast or forged. Some vanes are

made hollow to allow cooling air to flow through them. All nozzle

assemblies are made of very highstrength steel that withstands the

direct impact of the hot gases flowing from the combustion chamber.

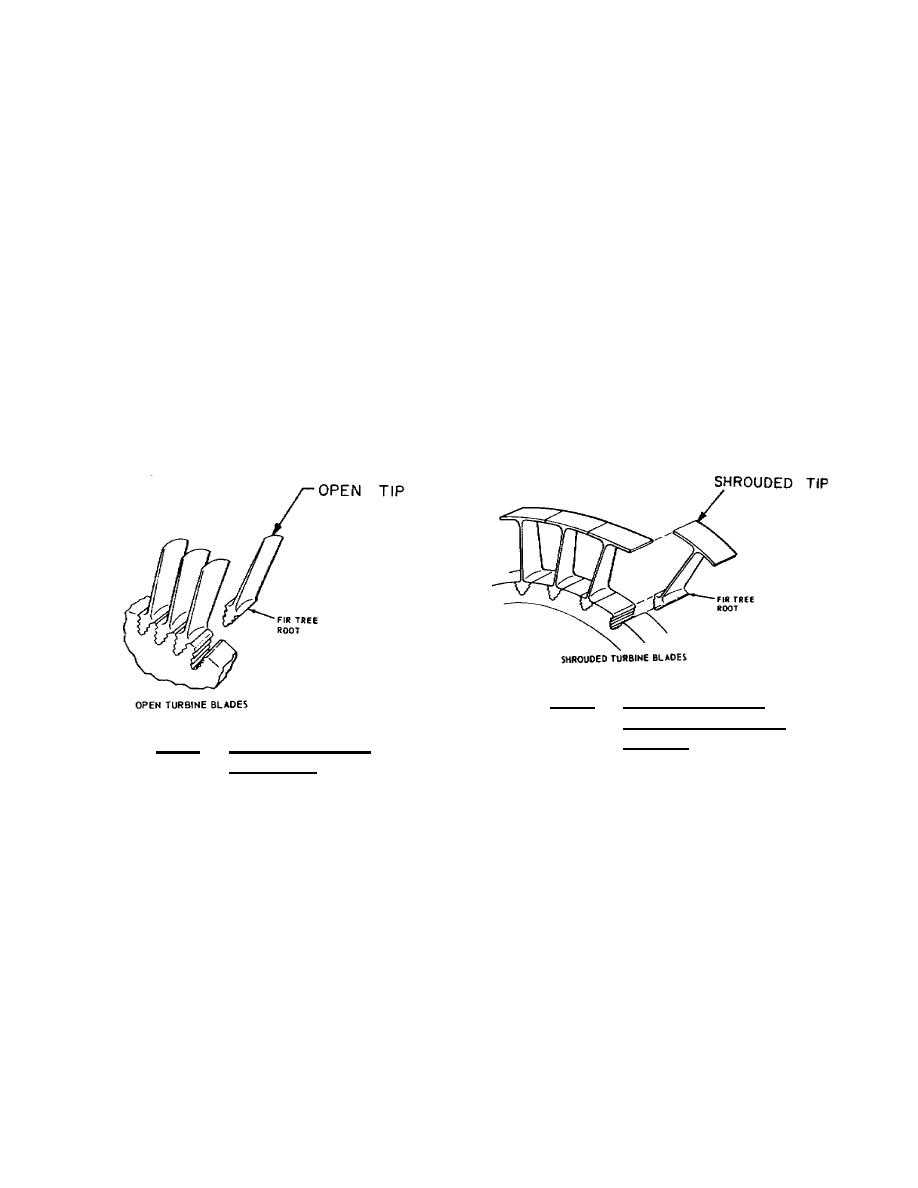

The turbine blades are attached to the disk by using the "fir

tree" design, shown in figure 1.27, to allow for expansion between

the disk and the blade while holding the blade firmly to the disk

against centrifugal loads. The blade is kept from moving axially

either by rivets or special locking devices. Turbine rotors are of

the opentip type as shown in figure 1.27, or the shroud type as

shown in figure 1.28.

Figure 1.28. Turbine Blade

"Fir Tree Root"

Shroud.

Figure 1.27.

Turbine Wheel

Open Tip.

The shroud acts to prevent gas losses over the blade tip and

excessive blade vibrations. Distortion under severe loads tends to

twist the blade toward low pitch, and the shroud helps to reduce this

tendency. The shrouded blade has an aerodynamic advantage in that

thinner blades can be used with the support of the shroud.

Shrouding, however, requires that the turbine run cooler or at

reduced rpm because of the extra mass at the tip.

Blades are forged or cast from alloy steel and machined and

carefully inspected before being certified for use. Manufacturers

stamp a "moment weight" number on the blade to retain rotor

42

Previous Page

Previous Page