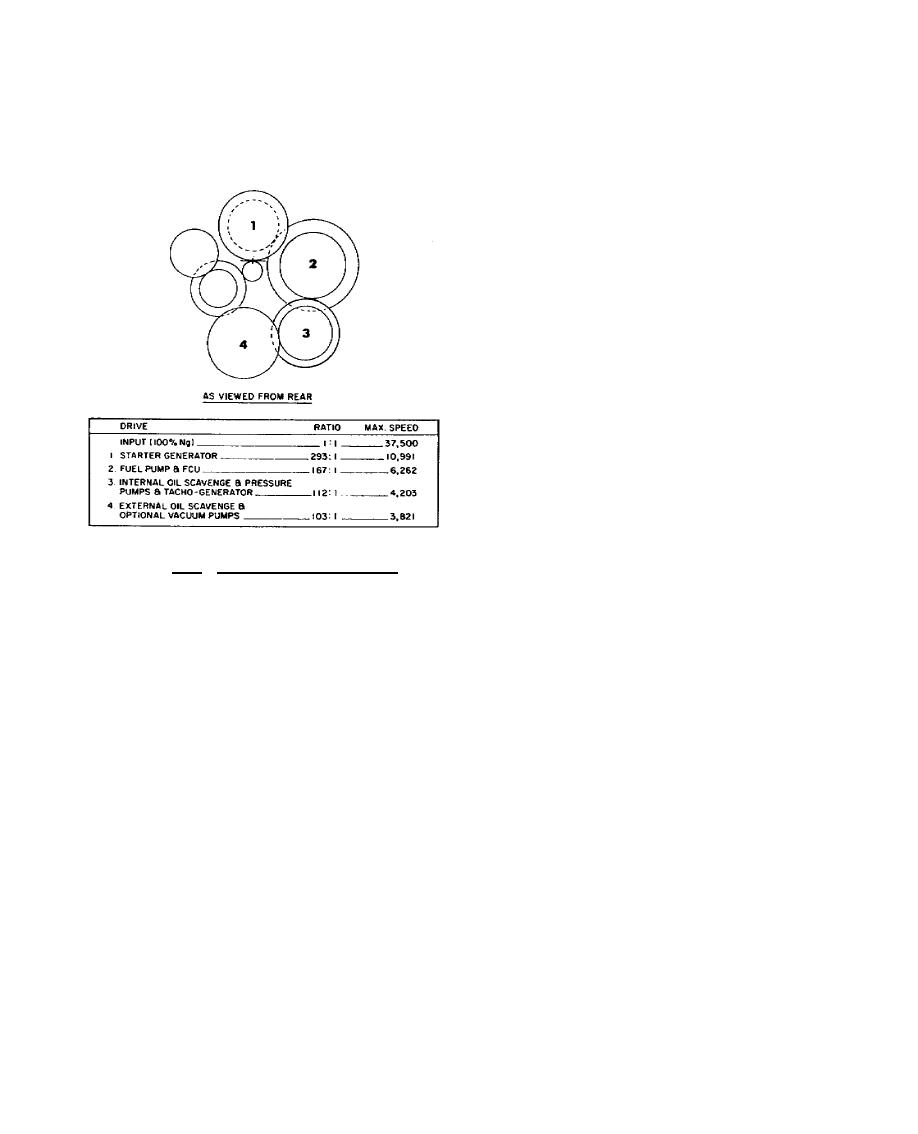

The rear casting forms an accessory gearbox cover with support bosses for the accessory drive

bearings and seals. The internal scavenge oil pump is secured inside the housing, and a second scavenge

pump is externally mounted. Mounting pads and studs are located on the rear face for the combined

starter-generator, the fuel control unit with the sandwich-mounted fuel pump, and the N1 tachometer-

generator. Three additional pads are available for optional requirements; see figure 9.11.

An oil tank filler cap and dipstick are located at

the eleven o'clock position on the rear housing.

A centrifugal oil separator mounted on the starter-

generator's drive gearshaft separates the oil from

the engine breather air in the accessory gearbox

housing.

9.11.

BEARING INSTALLATION

The compressor rotor assembly is

supported and secured in the rear section of the

gas generator case by two bearings. The outer

race of No. 1 ball bearing is held in its flexible

housings by a special nut and keywasher. The

split inner race, spacer, and rotor seal are stacked

against a shoulder on the compressor rear hub

shaft and secured by a cup-washer and special

nut. The outer flange of the No. 2 roller bearing

is attached to the gas generator centerbore by four

Figure 9.11. Accessory Gearbox Train.

bolts and tablock washers.

The compressor turbine disk holds the plain inner race stacked in position between front and

rear rotor seals on the compressor front stubshaft and a shoulder on the stubshaft. The bearing

installation of the T74 engine is illustrated in figure 9.12.

The power turbine disk and shaft assembly is supported and secured in the power turbine

shaft housing by the No. 3 and No. 4 bearings. Bearing No. 3 is a roller type, and No. 4 is a ball type.

238

Previous Page

Previous Page