d.

Engine oil filters. The oil filter

system consists of a main oil filter assembly and

five secondary oil filters. Three of these filters

are accessible for intermediate level maintenance.

These are the No. 2 bearing strainer, located at

the 3 o'clock position on the forward face of the

diffuser housing assembly, and the No. 4 and 5

bearing strainers located in the supply tube within

the exhaust diffuser.

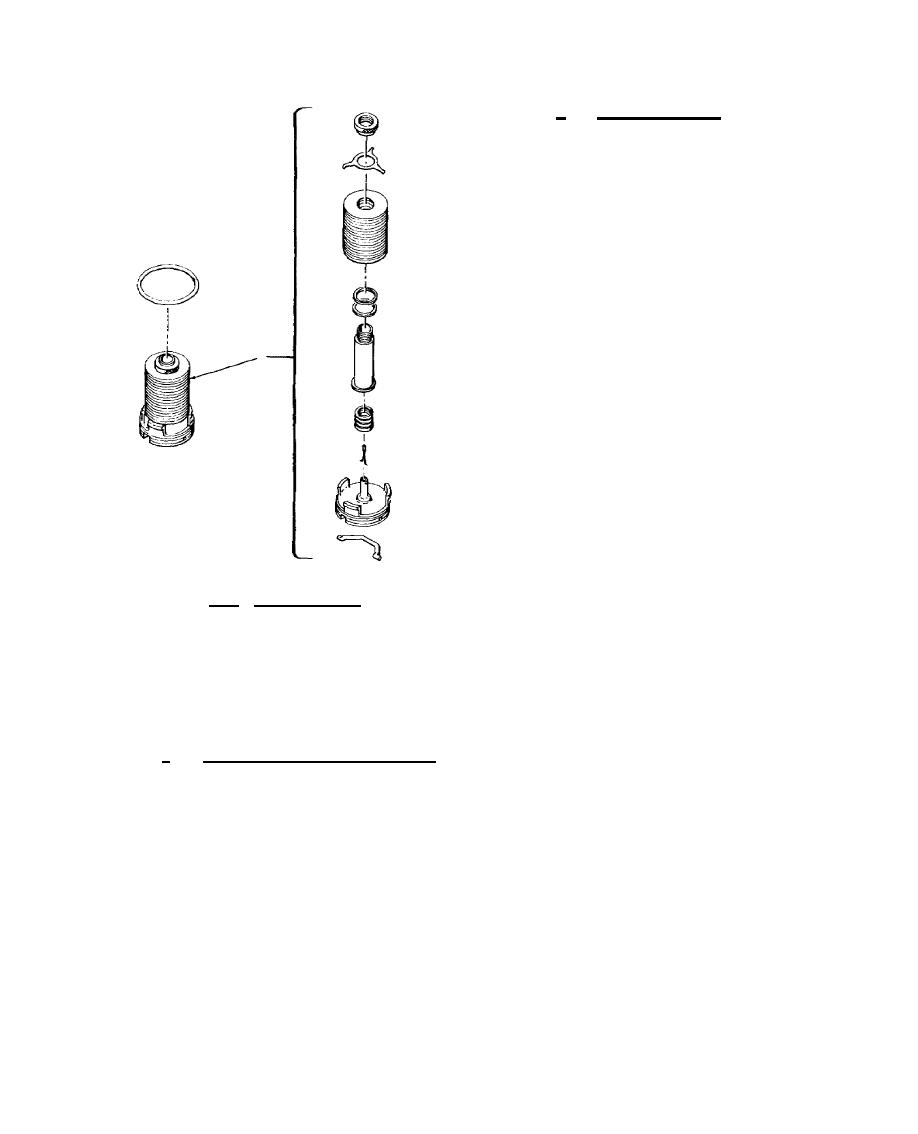

The main oil filter

assembly, illustrated in figure 5.20, is mounted on

the bottom of the accessory gearbox directly in

front of the main oil pump, or fuel boost pump.

5.20.

TORQUE METER SYSTEM

The Lycoming Electric Torquemeter

used on the T55 engine is the same type that is

used on the T53-L-701 covered in the previous

chapter. To save describing the system in detail

again, this paragraph is a brief review. When

torque is imposed on the engine power output

shaft, tension and compression stresses change the

magnetic reluctance of the shaft. This change in

magnetic reluctance is transmitted to an indicator

in the cockpit and read as percent (%) of torque.

Figure 5.20. Main Oil Filter.

5.21.

ELECTRICAL SYSTEM

The engine electrical system includes circuitry to facilitate starting, ignition, anti-icing, and all

engine-oriented electrical monitoring devices. The following subparagraphs discuss the operation of the

engine electrical system.

a.

Main electrical cable assembly. The main electrical cable assembly furnishes all

necessary interconnecting wiring between the main disconnect plug and the nine-branch electrical

connectors. The nine electrical accessories served by this cable are the gas producer tachometer

171

Previous Page

Previous Page