2.16.

SCAVENGE PUMPS

Although much larger in total capacity, scavenge pumps are

usually constructed in the same manner as pressure pumps. Engines

are generally provided with several scavenge pumps to drain oil from

various parts of the engine. Often such a pump shares the same

housing as the pressure pump. These pumps are used to draw the oil

from the sumps at the bearings, accessory gearbox housings, and other

drainage points and return the oil back to the tank.

2.17.

FILTERS

Three basic oil filters or strainers are made: cartridge,

screendisk, and screen. These filters are the same design as the

filters used in the fuel system, as covered in paragraph 2.8. The

main objective of a filter is to remove all foreign particles from

the lubricant without creating excessive back pressure against the

pumps. Filters are usually provided with bypass valves to permit the

flow of oil in case the filter becomes clogged.

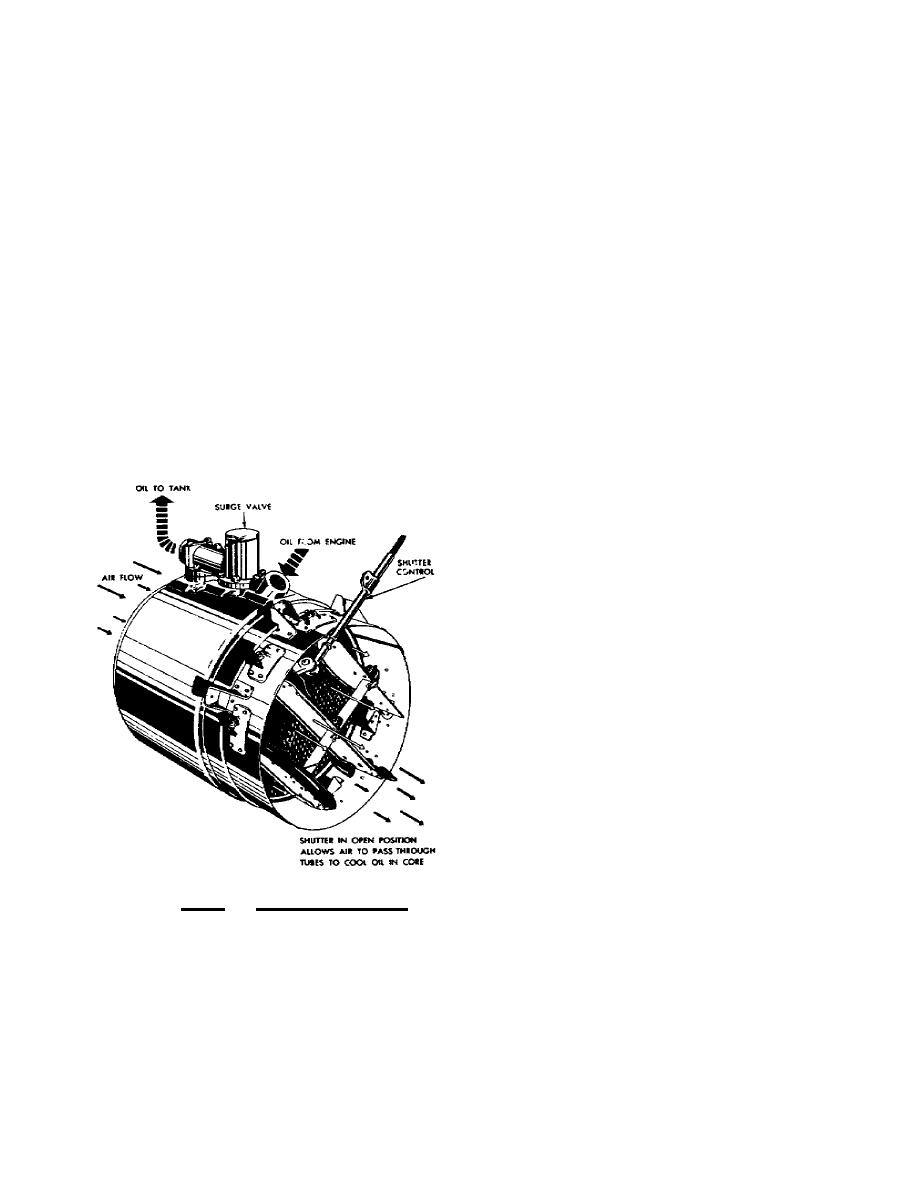

2.18. OIL COOLER

Oil coolers for aviation

gasturbine engines are either

simple oil radiators with air

cooling or the kind that uses

fuel as the cooling medium. The

latter type of unit is used on

the Lycoming T55 engine. The

fuel oilcooling unit is a heat

exchanger which transfers the

heat in the oil to the fuel

flowing to the fuel nozzles.

Since the fuel flow through the

cooler is much greater than the

oil flow, the fuel is able to

absorb a considerable amount of

heat from the oil, thereby

reducing the size and weight of

the cooler. The fuel oilcooler

is shown in figure 2.11 on page

57. An air cooler is shown in

Figure 2.14. Air Oil Cooler.

figure 2.14.

2.19.

SPRAY OIL JETS

The lubrication method most generally used is known as a

calibrated system, where oil is specifically controlled by a

calibrated

61

Previous Page

Previous Page