2.14.

OIL TANKS

Most gas turbine engines are of the drysump type, meaning the

on is stored separately from the engine, or the tank may be attached

to a structural part of the engine. Usually constructed of welded

aluminum or steel, it can contain a venting system, a deaerator

(baffles) to separate air from the oil. Some systems use an oil

level transmitter to indicate quantity, where others have a dipstick

or visual sight gage.

2.15.

PRESSURE PUMPS

Oil pumps for turbine engines are usually of the positive

displacement gear type, with a relief valve to prevent excessive

pressure. A modified geartype pump is called the "gerotor pump."

The geartype pump consists of a driving and driven gear. The

pump is driven from the engine accessory section and causes the oil

to pass around the outside of the gears in pockets formed by the gear

teeth and the pump casing. The pressure developed is proportional to

engine rpm up to the point where the pressure relief valve opens and

limits the pressure output of the pump.

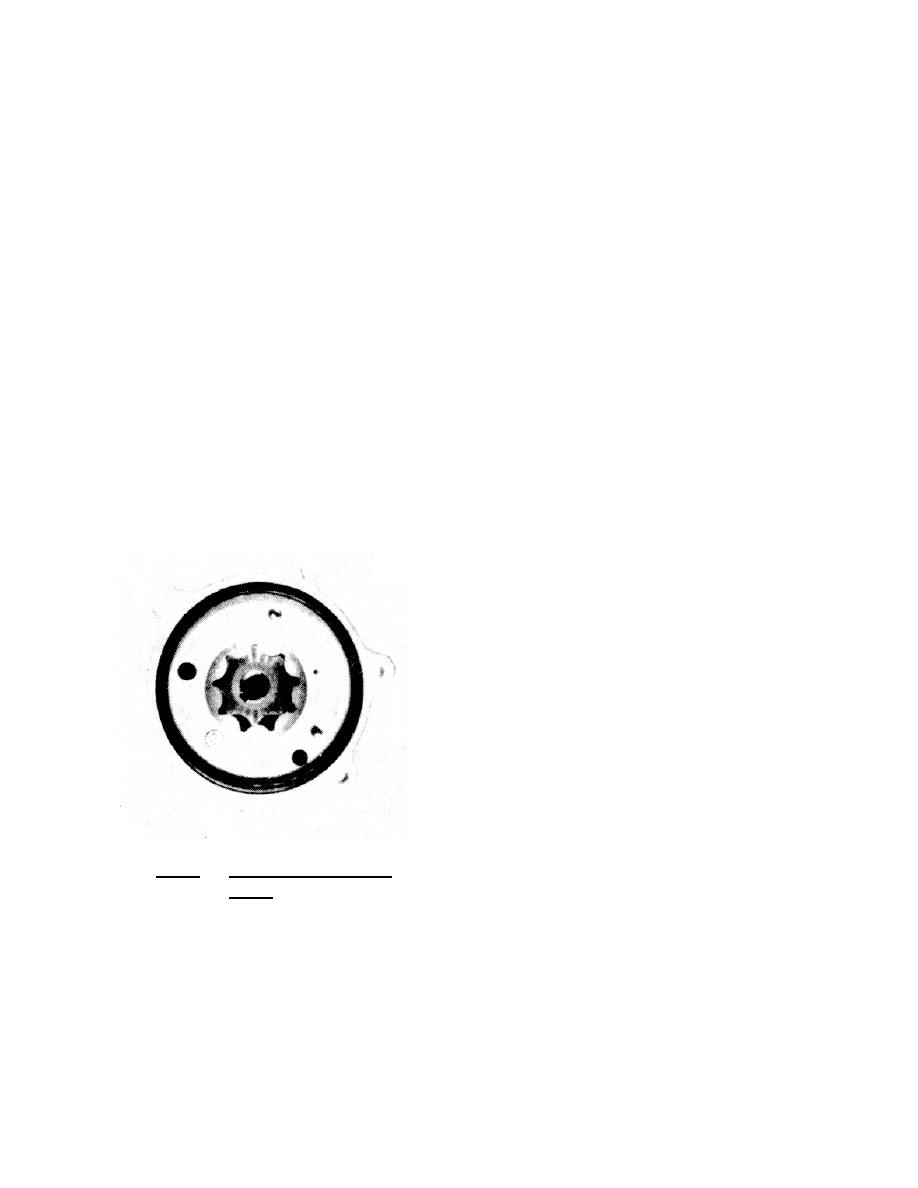

The gerotor pump has two

moving parts, an inner toothed

element meshing with an outer

toothed element. The inner

element has one less tooth than

the outer, and the missing tooth

provides a chamber to move the

fluid from the intake to the

discharge port. Both elements

are mounted eccentrically to each

other, the inner one mounted on

the shaft and the outer one

meshed with it. Figure 2.13 is a

picture of the gerotor pump,

showing both inner and outer

Figure 2.13.

Gerotor Booster

toothed elements.

Pump.

60

Previous Page

Previous Page