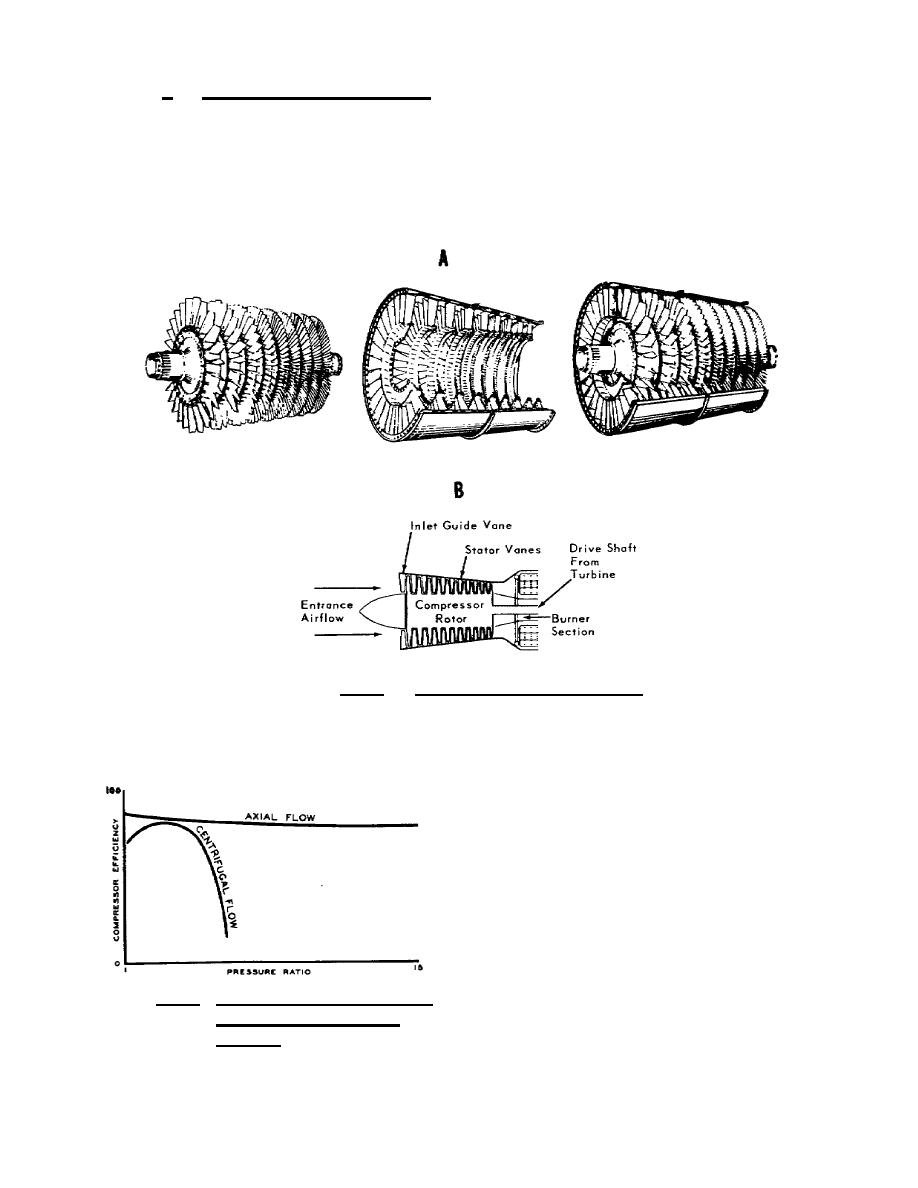

b. Axialflow compressor. The air is compressed, as the name

implies, in a direction parallel to the axis of the engine. The

compressor is made of a series of rotating airfoils called rotor

blades, and a stationary set of airfoils called stator vanes. A

stage consists of two rows of blades, one rotating and one

stationary. The entire compressor is made up of a series of

alternating rotor and stator vane stages as shown in figure 1.13.

Figure 1.13. Axialflow Compressor.

Axial flow compressors have the advantage of being capable

of very high compression ratios with relatively high efficiencies;

see figure 1.14. Because of the

small frontal area created by

this type of compressor, it is

ideal for installation on high

speed aircraft. Unfortunately,

the delicate blading and close

tolerances, especially toward the

rear of the compressor where the

blades are smaller and more

numerous per stage, make this

compressor highly susceptible to

Figure 1.14. Compressor Efficien

foreignobject damage. Because

cies and Pressure

of the close fits required

Ratios.

Previous Page

Previous Page