AVCO) and the 13 is referred to as the "dash number." These are

also always odd numbers, if the engine was developed for the Air

Force/Army. The dash number designates the particular version of

this model engine. When a production model is improved by major

modifications, the dash number is changed.

In the past the Army has been getting their engines through

the Air Force, using Air Force designators. However, now the Army

has its own series of number designators. The first engine procured

under the new system was the T700GE700 engine. The next engine

developed for the Army will be the T701manufacturer's codethree

digit dash number. The engines that were in the Army inventory

previous to this new designator system will keep their present

designators. However, when these models are improved, they will get

the new threedigit number for a dash number. For example the

improved version of the T53L15 is the T53L701.

1.18.

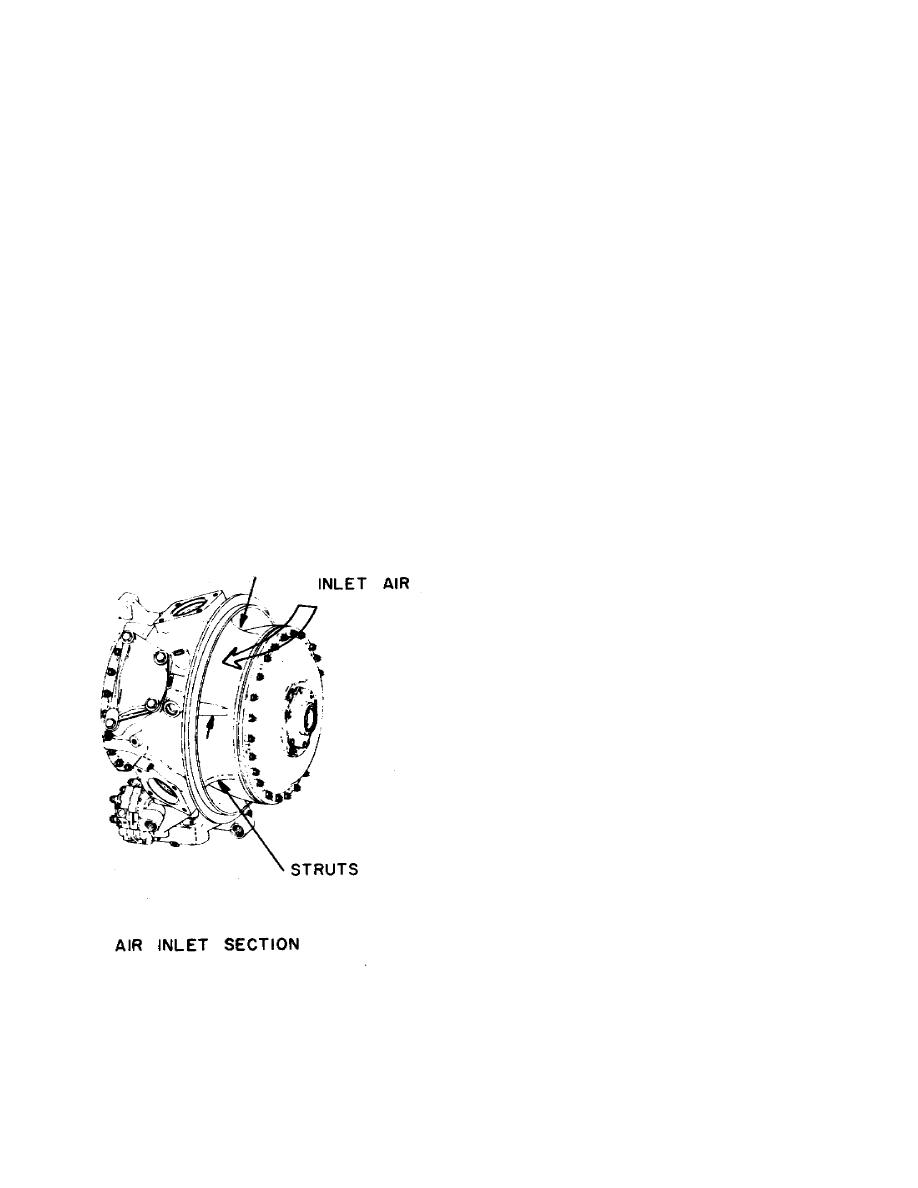

AIR INLET SECTION

The amount of air required by a gas turbine engine is

approximately ten times that of a reciprocating engine. The air

inlet is generally a large, smooth aluminum or magnesium duct which

must be designed to conduct the air into the compressor with minimum

turbulence and restriction. The air inlet section may have a variety

of names according to the desire of the manufacturer. It may be

called the front frame and accessory section, the air inlet assembly,

the front bearing support and shroud assembly, or any other term

descriptive of its function. Usually, the outer shell of the front

frame is joined to the center portion by braces that are often called

struts. The antiicing system directs compressor discharge air into

these struts. The temperature of this air prevents the formation of

ice that might prove damaging to the engine. Antiicing systems are

discussed further in the chapter covering the engines they may be

installed on. Figure 1.11 illustrates the variety of inlet duct

designs of Army aircraft.

25

Previous Page

Previous Page