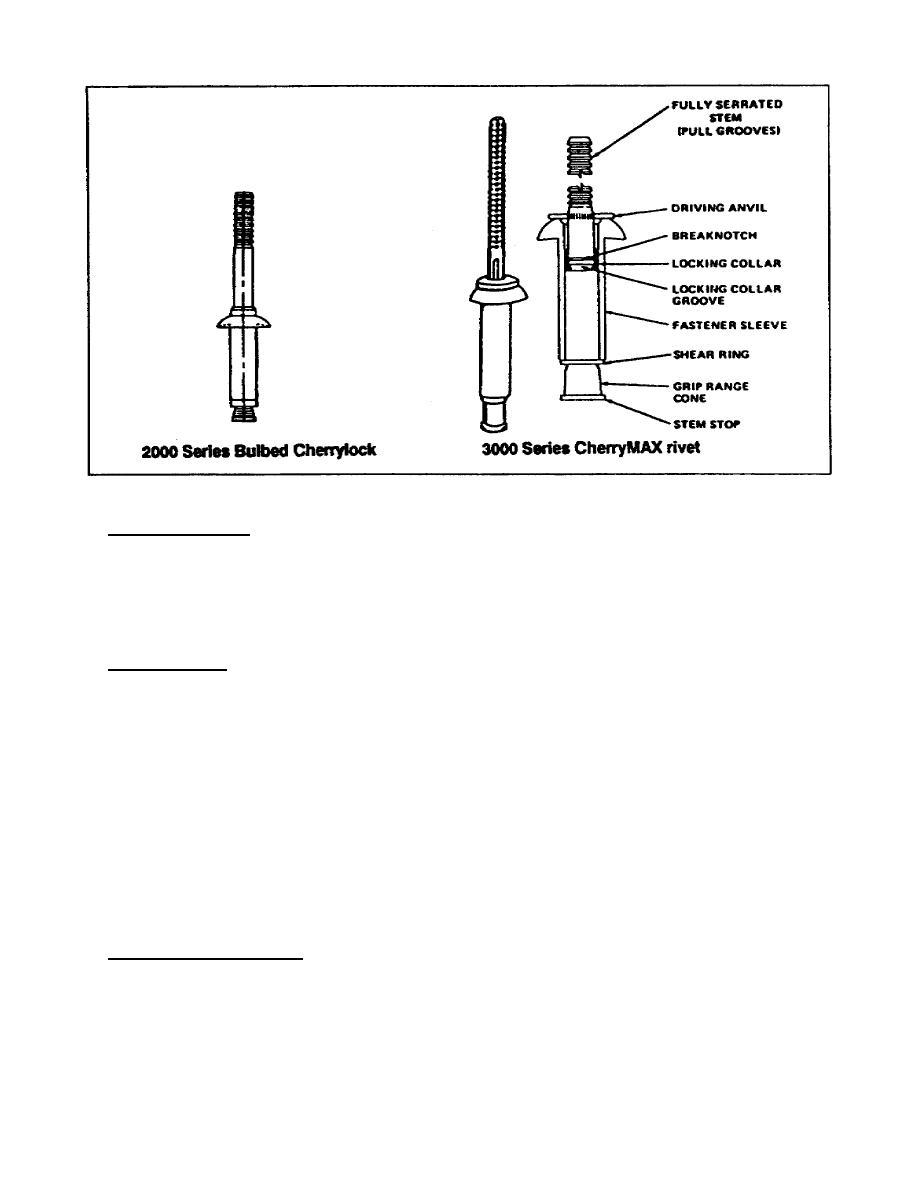

Figure 1-12a.

Self-Plugging (Mechanical Lock) Rivets.

Rivet Removal. When a rivet has to be replaced, it must be removed

carefully so that the rivet hole will retain its original size and

shape and the rivet will not need to be replaced with one of the next

larger size.

If the rivet is not removed properly, the strength of

the joint may be weakened. Hand tools, power tools, or a combination

of both may be used to remove rivets.

Solid-Shank. To remove a solid-shank rivet, use a drill one size

smaller than the rivet shank to drill through the rivet head.

Be

careful not to drill too deep because the rivet shank will then turn

with the drill and cause a tear.

Insert a drift punch diagonally into the drilled hole and knock the

rivet head off by lightly striking the drift punch.

Drive the rivet shank out with a drift punch slightly smaller than

the diameter of the shank. On thin metal or unsupported structures,

support the sheet with a bucking bar while driving out the shank. If

the shank is unusually tight after the rivet head is removed, drill

the rivet about two-thirds through the thickness of the material and

then drive the rest of the shank out with a drift punch.

Mechanical-Locking.

To remove a mechanical-locking rivet, use the

following steps.

31

AL0992

Previous Page

Previous Page