plate, and rivnuts without keys are used for blind riveting where

torque loads are not imposed.

Closed-end rivnuts are used when a

sealed installation is required. The installation of a rivnut is not

complete unless it is plugged, either with one of the plugs designed

for that purpose or with a screw. A rivnut does not develop its full

strength when left hollow.

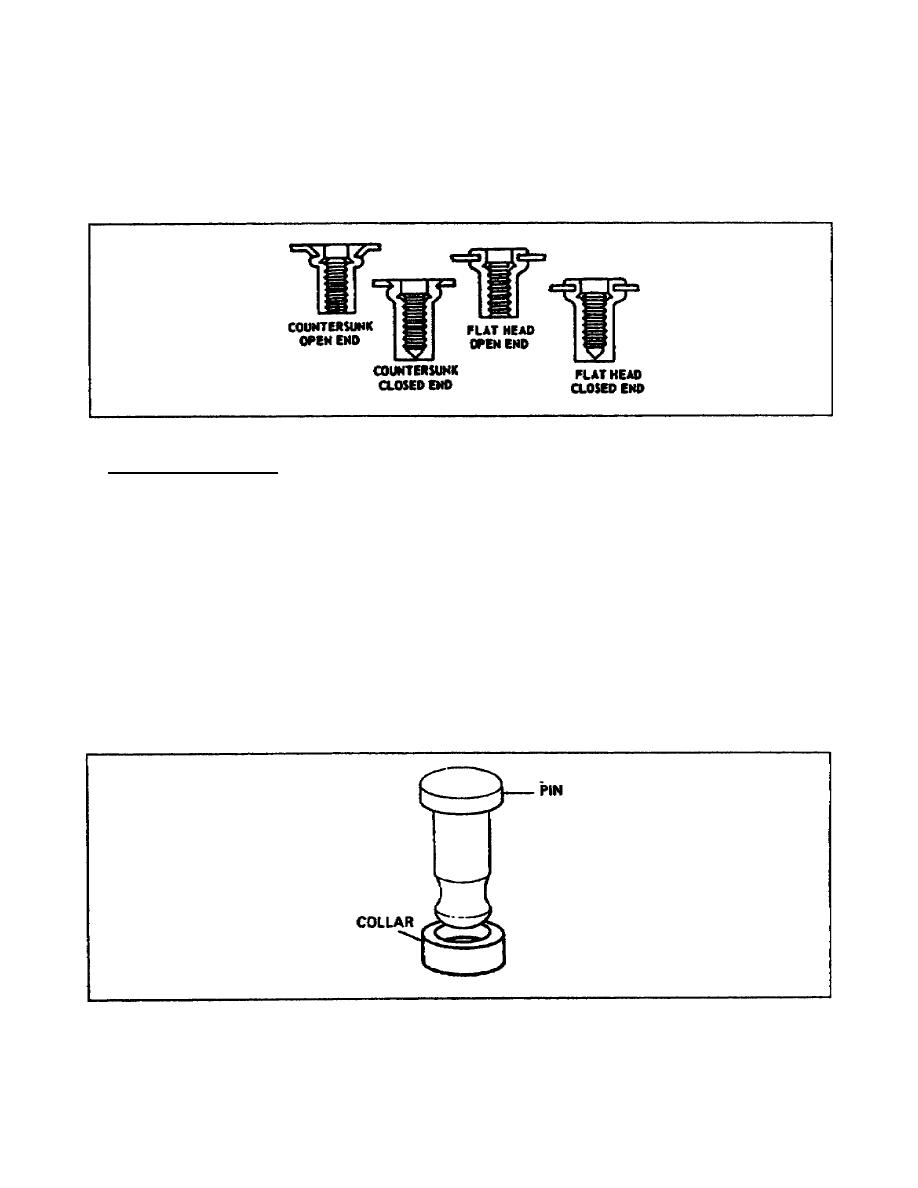

Figure 1-13.

Countersunk and Flat Head Rivnuts.

Hi-Shear Rivets.

The Hi-Shear rivet, essentially a threadless

bolt, consists of two parts, the pin and the collar as shown in

Figure 1-14. These rivets are classified as special rivets, but are

not of the blind type.

Access to both sides of the material is

required to install the rivet.

Hi-Shear rivets have the same shear

strength as bolts of equal diameters and have about 40 percent of the

weight of a bolt. In addition, they require only about one-fifth as

much time to install as a bolt, washer, and nut combination.

They

are approximately three times as strong as solid shank rivets.

The

pin is headed at one end and is grooved about the circumference at

the other. The collar is swaged onto the grooved end to make a firm,

tight fit. Hi-Shear rivets are made from a variety of materials and

are used only in shear applications.

In addition, they must not be

used where the grip length is less than the shank diameter.

Figure 1-14.

Hi-Shear Pin.

34

AL0992

Previous Page

Previous Page