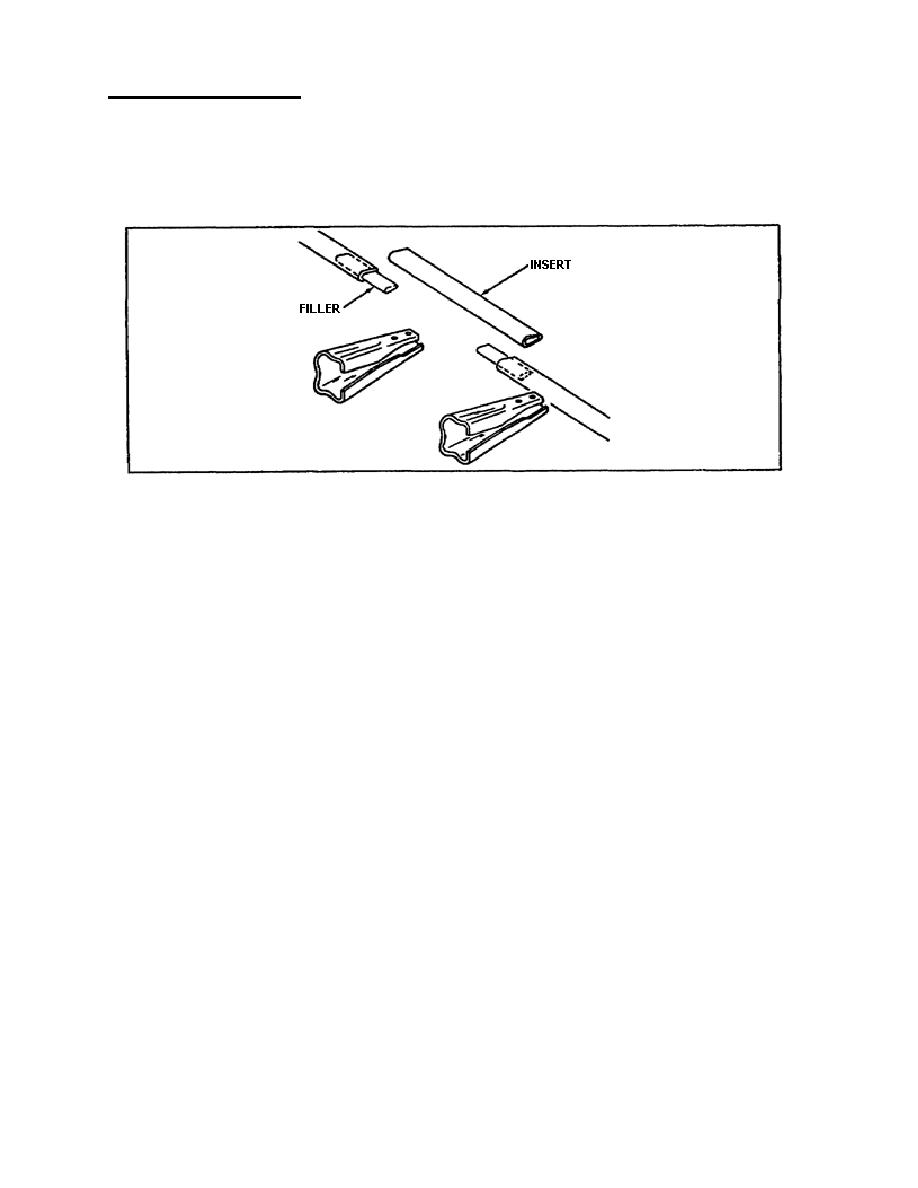

Repair Near a Rib.

To repair damage occurring at or near a rib,

first remove sufficient trailing edge material to allow a complete

splice to fall between the ribs.

This usually requires two splices

joined by an insert piece of similar trailing edge material or of

formed sheet stock. The repair is similar to that for damage between

ribs. Figure 2-18 illustrates a trailing edge repair at a rib.

Figure 2-18.

Trailing Edge Repair Near a Rib.

SUMMARY

The elements for stringer repair consists of reinforcement and filler

splices and rivets. Reinforcement splices must extend at four times

the width of the stringer leg on each side of the damaged area.

A

reinforcement splice's cross-sectional area strength must equal or

exceed the stringer's.

Damage must be trimmed to a smooth contour

and corner radii.

The filler patch must be of proper thickness and

shape and 1/32 inch shorter in length than the trimmed out section.

This allows 1/64 inch clearance between the stringer stub ends and

the filler splice ends to prevent stress development between the

ends.

When possible, maintain the original rivet pattern in the

repair.

This is achieved by having the trimmed-out area lie midway

between two rivets.

This repair is authorized only when the damage

does not exceed two-thirds of the width of one leg of the stringer

and is not longer than 12 inches. If the damage is greater than two-

thirds of the leg width, the repair method shown in Figure 2-11 must

be used.

Longeron repair is somewhat similar to stringer repair; however,

heavier rivets or bolts are used because of the longeron's greater

weight. If bolts are used, bolt holes must be drilled for a light-

drive fit.

Rivet spacing on longeron repairs must be kept between

four and six rivet diameters.

84

AL0992

Repair on spars may not be permitted because spars are highly

stressed members.

If the repair is permitted, the workmanship must

Previous Page

Previous Page