repairing the cap strip and stringer and making a new nose rib and a

skin panel.

When repairing a leading edge, use only the procedures

prescribed in the applicable manual.

TRAILING EDGE REPAIR

The rearmost part of an airfoil is the trailing edge. It is usually

a metal strip that forms or shapes the edge by tying the ends of a

rib section together and joining the upper and lower skins.

Though

not structural members, trailing edges are highly stressed and from

time to time require repair.

The paragraphs that follow discuss

kinds of damage and damage inspection and location.

Trailing Edge Damage. A trailing edge's damage may be limited to

one point or extended over the length between two or more rib

sections. In addition to damage from collision or careless handling,

trailing edges are particularly subject to corrosion from collected

or trapped moisture.

Damage Inspection.

Thoroughly inspect the damaged area before

starting repairs; and determine the extent of damage, the type of

repair needed, and the way the repair should be made. When repairing

trailing edges, the repaired area must have the same contour and be

the same material with the same composition and temper as the

original section.

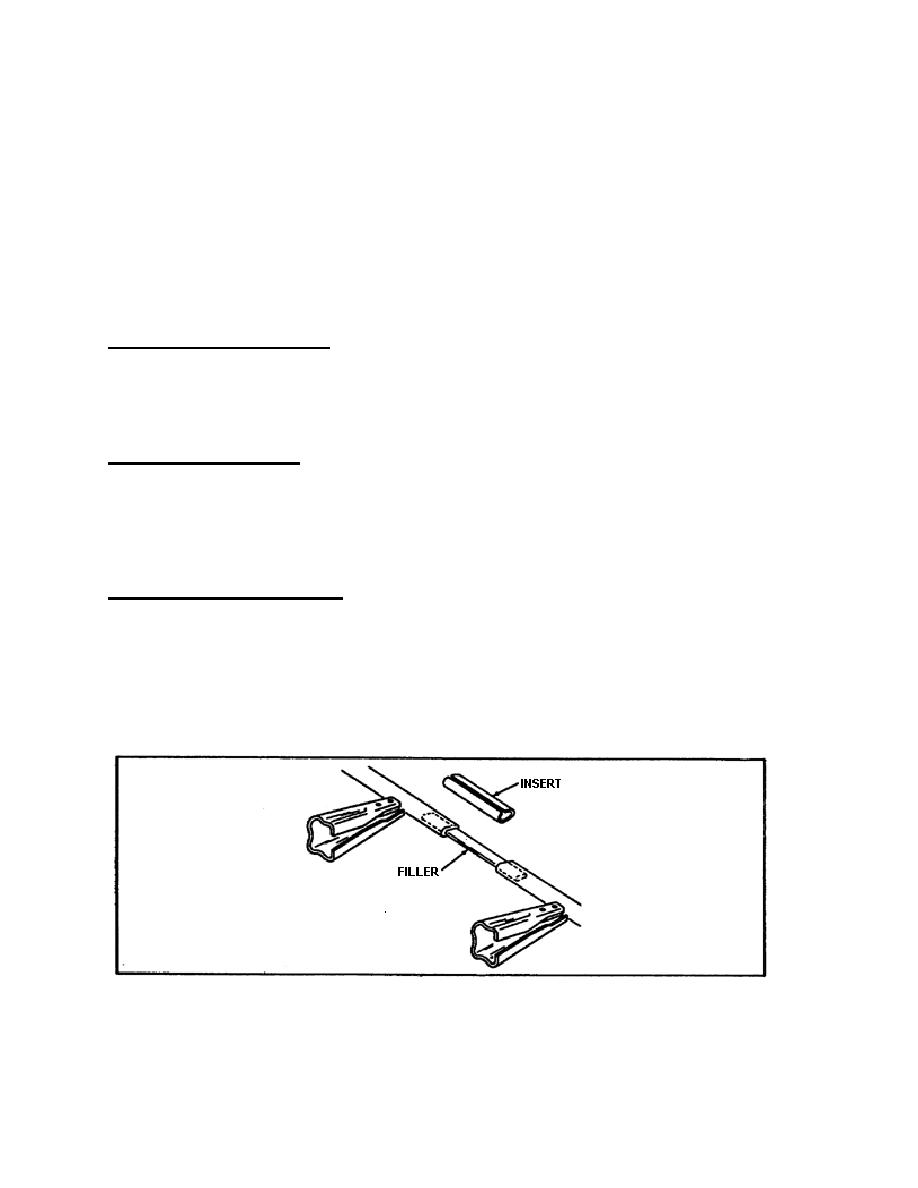

Repairs Between Ribs.

Damage occurring in the trailing edge

section between the ribs can be repaired as shown in Figure 2-17.

Cut out the damage area and make a filler of either fiber or cast

aluminum alloy to fit snugly inside the trailing edge. Then make an

insert piece of the same material as the damaged section, and shape

it to match the trailing edge.

Assemble the pieces as shown and

rivet them into place. Use countersunk rivets, and form countersunk

shop heads to get a smoother contour.

Figure 2-17.

Trailing Edge Repair Between Ribs.

83

AL0992

Previous Page

Previous Page