overload without damage. The direction of rotation of a hydraulic motor can be changed by reversing

the flow of fluid into the ports of the motor.

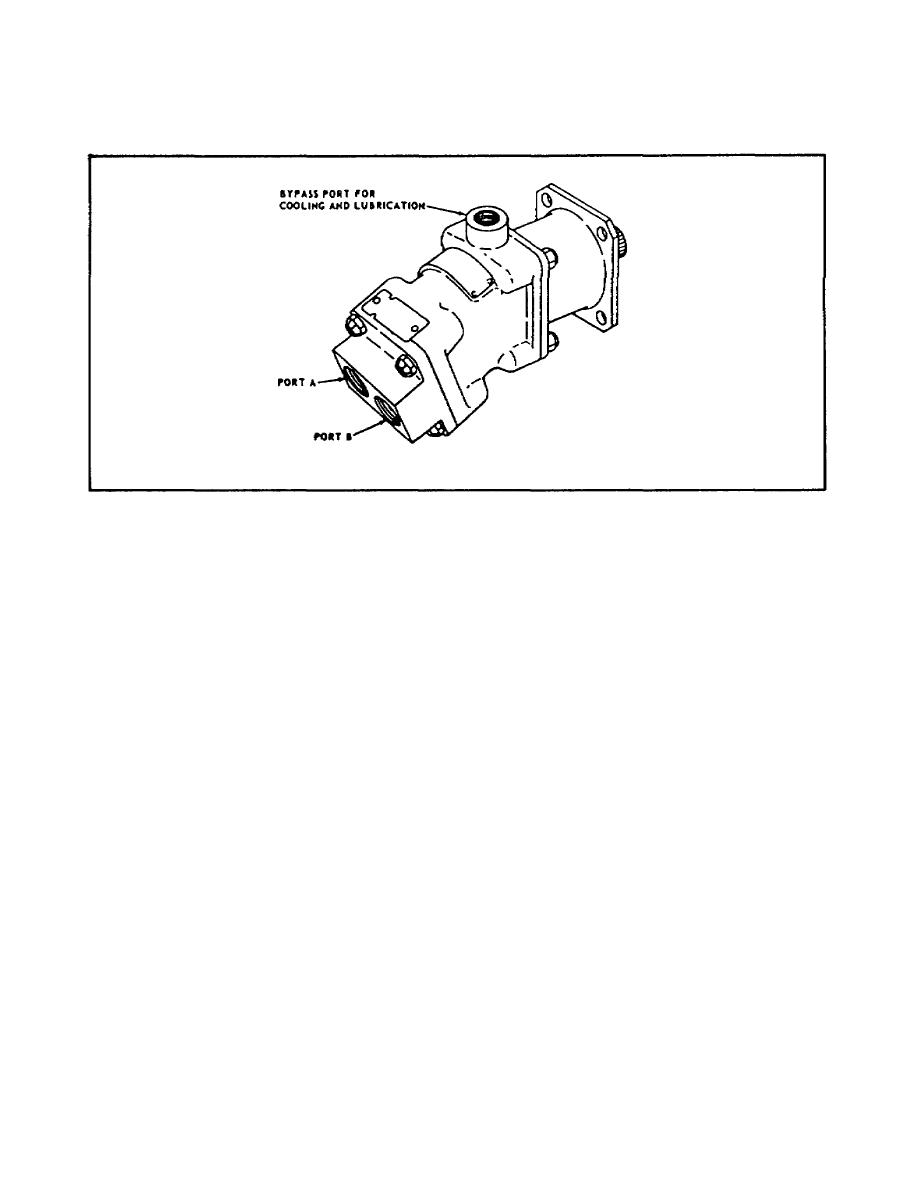

Figure 1-13. Typical Hydraulic Motor.

SUMMARY

The basic components of any hydraulic system are reservoirs, filters, and pumps (hand or power-driven).

The reservoir holds the fluid supply for the system and helps cool the fluid. Filters are used to ensure

that no contamination reaches the components in a hydraulic system. The pleated micronic filter is the

most common.

The pump converts mechanical energy to fluid flow. The most common power-driven pump is the

piston pump. In all but the simplest hydraulic systems, variable-delivery pumps are used. A variable-

delivery pump delivers only the amount of fluid demanded by the system. This is accomplished through

the use of a compensator.

Depending on the type of aircraft, hydraulic accumulators and hydraulic motors can also be found in the

system. Accumulators are used primarily to supply pressure for starting auxiliary power units and

emergency hydraulic pressure. Hydraulic motors perform a variety of functions, including raising and

lowering cargo doors, operating rescue hoists, and positioning wing flaps.

17

AL0926

Previous Page

Previous Page