eventual engine failure. Engine cleaning procedures can be found in the appropriate aircraft or engine

maintenance manual. The compressor of the T63 must never be cleaned with an ordinary cleaning

solvent, because this will dissolve the plastic coating on the inside of the compressor case and cause

engine failure.

A control valve is mounted on the compressor case assembly to bleed air off the 5th stage of

the compressor during starting and all engine operations at low pressure ratios.

The compressor diffuser assembly consists of stainless steel front and rear diffusers and a

magnesium alloy scroll. The scroll collects the air and delivers it to two elbows. Compressor-discharge

air tubes deliver compressed air from the outlet of the elbows to the combustion outer case. The

diffuser scroll has five ports from which air can be bled or compressor discharge air pressure sensed.

Two of these ports are customer bleed air ports, and the remaining ports are used by the anti-icing valve,

fuel control pressure sensing, and bleed air pressure sensing. Customer air ports are used by the airframe

manufacturer to tap bleed air to run pumps, heaters, and so forth.

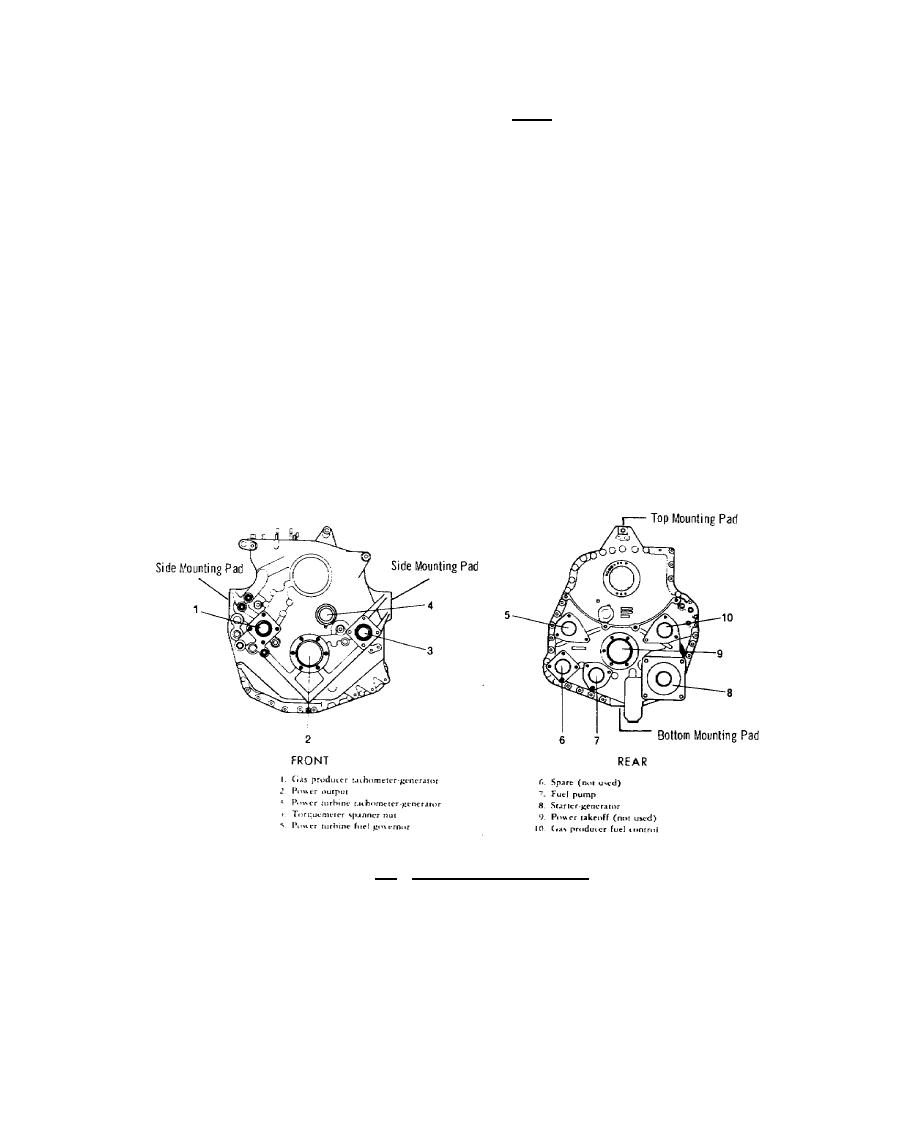

7.5.

ACCESSORY GEARBOX SECTION

Shown in figure 7.4, the accessory gearbox is the primary structural member of the engine.

All engine components, including

Figure 7.4. Accessory Gearbox Case.

193

Previous Page

Previous Page