called primary air and that for cooling is secondary air. The

secondary air is controlled and directed by holes and louvers in the

Igniter plugs function only during starting, being cut out of

the circuit as soon as combustion is selfsupporting. On engine

shutdown, or, if the engine fails to start, the combustion chamber

drain valve, a pressureactuated valve, automatically drains any

remaining unburned fuel from the combustion chamber. All combustion

chambers contain the same basic elements: a casing or outer shell, a

perforated inner liner or flame tube, fuel nozzles, and some means of

initial ignition. The combustion chamber must be of light

construction and is designed to burn fuel completely in a high

velocity airstream. The combustion chamber liner is an extremely

critical engine part because of the high temperatures of the flame.

The liner is usually constructed of welded highnickel steel. The

most severe operating periods in combustion chambers are encountered

in the engine idling and maximum rpm ranges. Sustained operation

under these conditions must be avoided to prevent combustion chamber

liner failure.

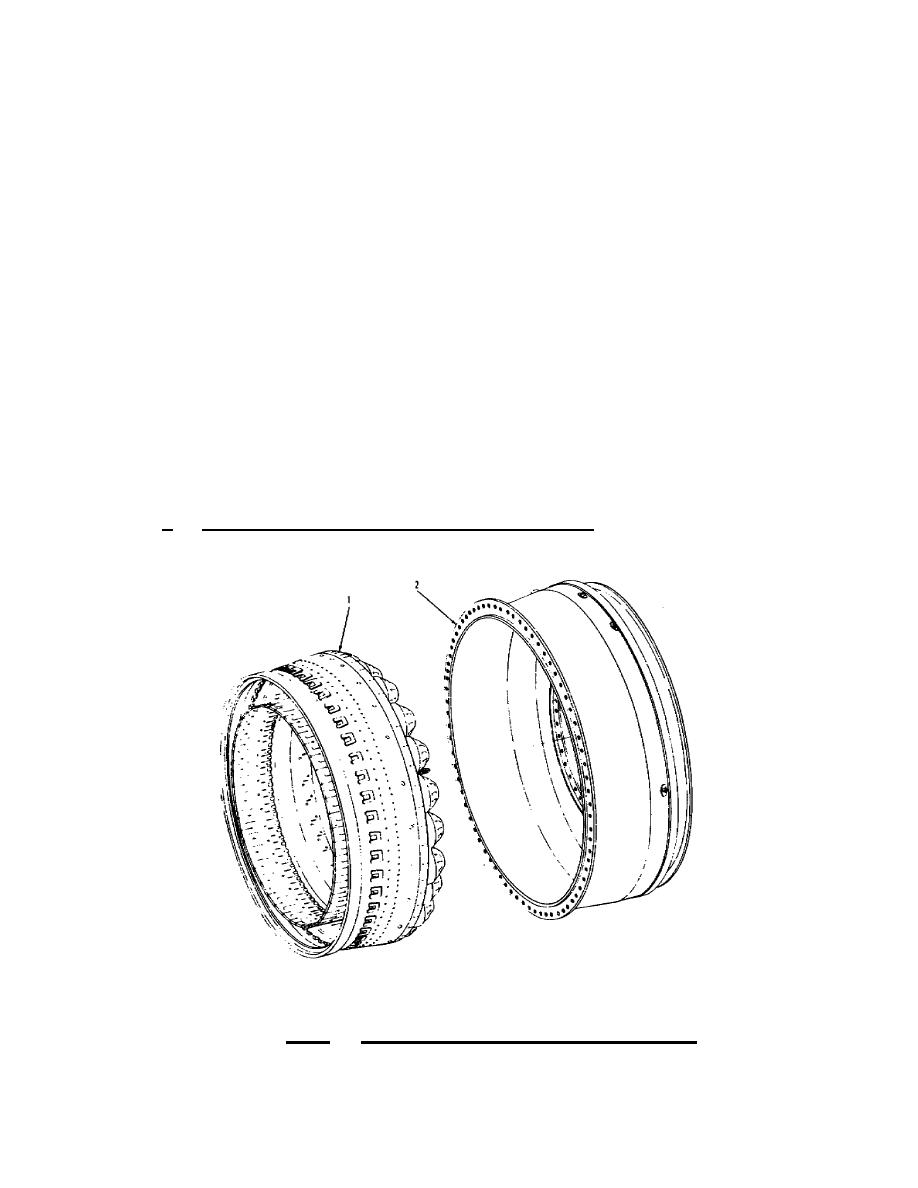

a. The annulartype combustion chamber shown in figure 1.18

is used in engines of the axialcentrifugalflow compressor de

1. ANNULAR TYPE COMBUSTION CHAMBER LINER

2. COMBUSTION CHAMBER HOUSING ASSEMBLY

Figure 1.18. Annulartype Combustion Chamber.

36

Previous Page

Previous Page