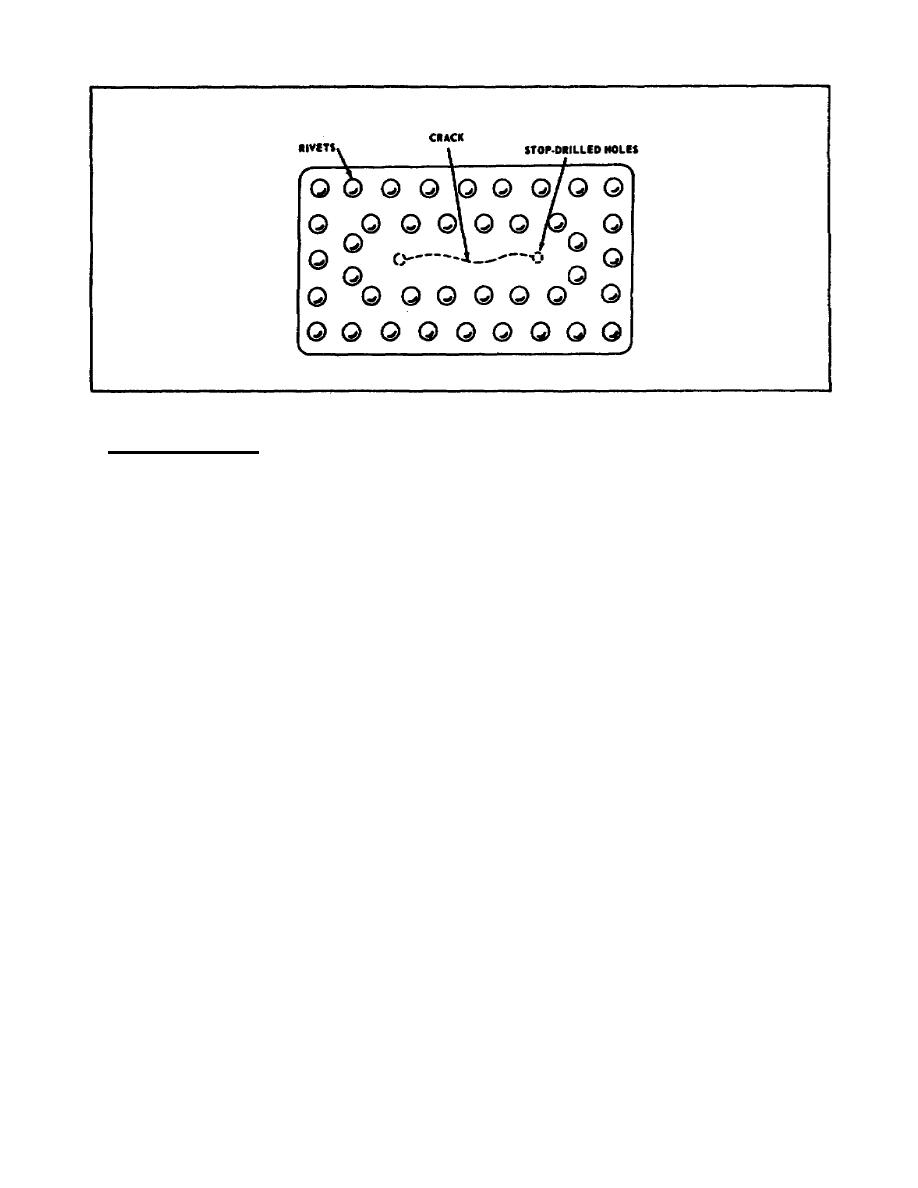

Figure 2-3.

Lap Patch for a Crack.

Flush Patches.

Flush patches in locations free of internal

structures are relatively easy to install.

This is especially true

where there is an access door or plate through which rivets can be

bucked.

In inaccessible areas, the flush patch can be used by

substituting blind rivets for standard rivets, where permitted.

However, ways of inserting the doubler through the opening must be

devised. A doubler is the piece of material used to back up, double,

or strengthen the filler patch.

One such method is illustrated in

Figure 2-2. The doubler has been split. To insert the doubler, slip

one edge under the skin and turn the doubler until it slides into

place under the skin.

Notice in the figure that a screw has been

installed temporarily as a handle to help insert the doubler.

This

type of patch is generally recommended for holes up to 1 1/2 inches

in diameter. Usually holes larger than 1 1/2 inches are trimmed to a

rectangular or square shape. All corners must be rounded to at least

a 1/2-inch radius.

Figure 2-4 shows such rounded corners.

In all

flush patches the filler must be of the same gage and material as the

original skin.

Generally, the doubler must be of material one gage

heavier than the skin.

Figure 2-5 shows a flush patch over an

internal structure.

63

AL0992

Previous Page

Previous Page