The Screw Flaring Tool.

There are two kinds of screw flaring

tools: one threaded and the other with a plain die. The stem of the

plunger on the screw flaring tool is threaded so that its pointed end

is forced into the tube by turning instead of by tapping with a

hammer.

The screw flaring tool also has the advantage of the tube

being visible, so it is easy to determine when the flare is

completed.

The Combination Flaring Tool.

The combination flaring tool is

designed to single-flare all grades of aircraft tubing including

stainless steel.

This tool can also form double-lap flare in

aluminum and copper tubing.

The component parts of the combination

flaring tool are: clamp blocks, a rotor that incorporates a punch for

forming double-lap flares, and a cone-shaped punch for forming single

flares. With each tool, there are two sets of die blocks; each set

has four accurately machined grooves to accommodate four different

sizes of tubing.

The two sets of die blocks make it possible to

flare eight different sizes of tubing. A clamp screw is used to hold

the tube between the die blocks, and a compression screw is located

in front of the dial containing the flaring punches. A slide stop is

used for setting the tube for the proper depth of flare.

DOUBLE FLARES

Double flaring is required on all 5052 aluminum alloy tubing with

less than 1/2-inch OD. The double flare provides a double thickness

of metal at the flare itself.

This double thickness reduces the

danger of cutting the flare by overtorquing during assembly and also

minimizes the danger of flare failure.

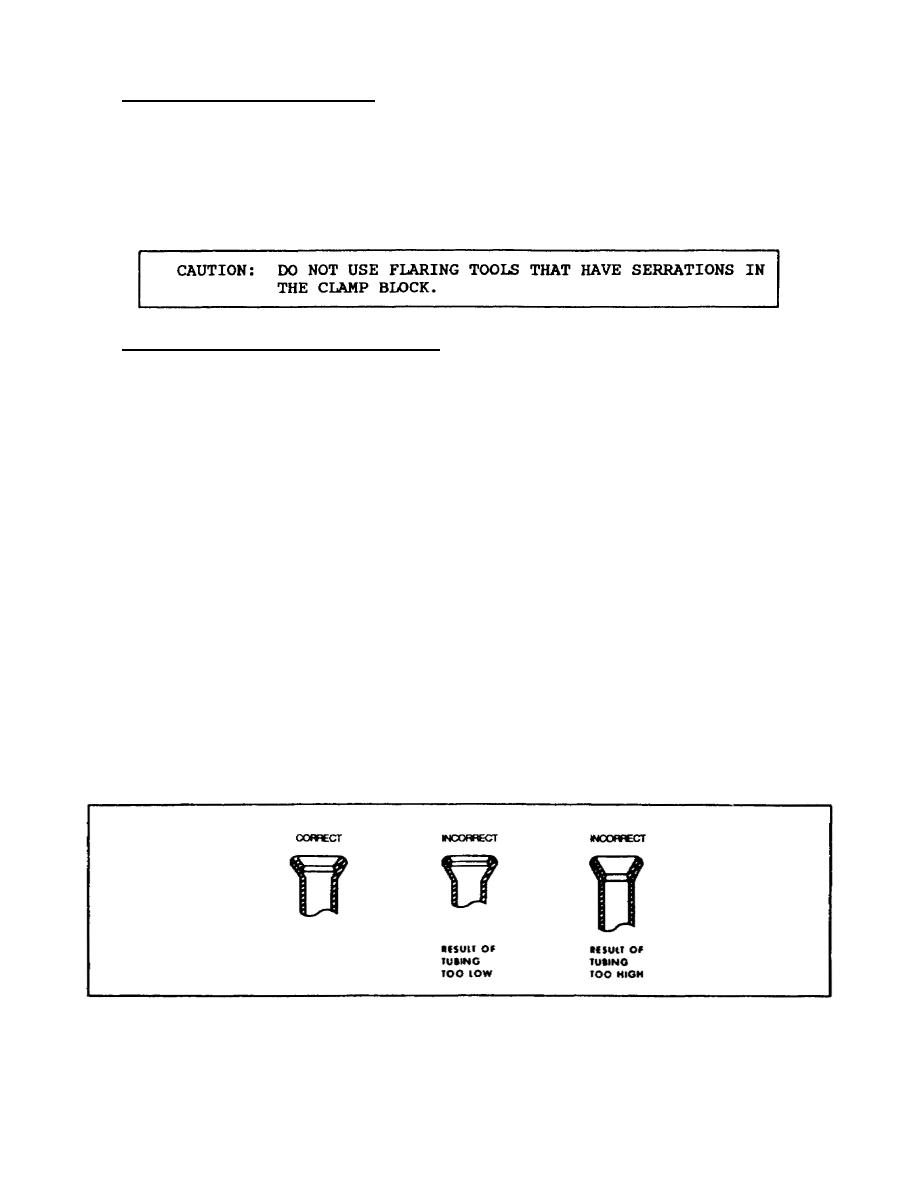

Examples of correct and

incorrect double flares are shown in Figure 2-9.

Figure 2-9.

Correct and Incorrect Double Flares.

42

AL0907

Previous Page

Previous Page