Hacksaw.

If a cutting tool is not available, use a fine-tooth

hacksaw, preferably one with 32 teeth per inch.

Since it is

difficult to get a good, square, flush cut on the tube with this

method, the tube end must be filed after the cut is made.

During

hacksaw cutting and filing, the tube must be clamped in tube blocks

or other suitable holders to prevent scratching or bending and to aid

in producing a 900 cut on the tube end.

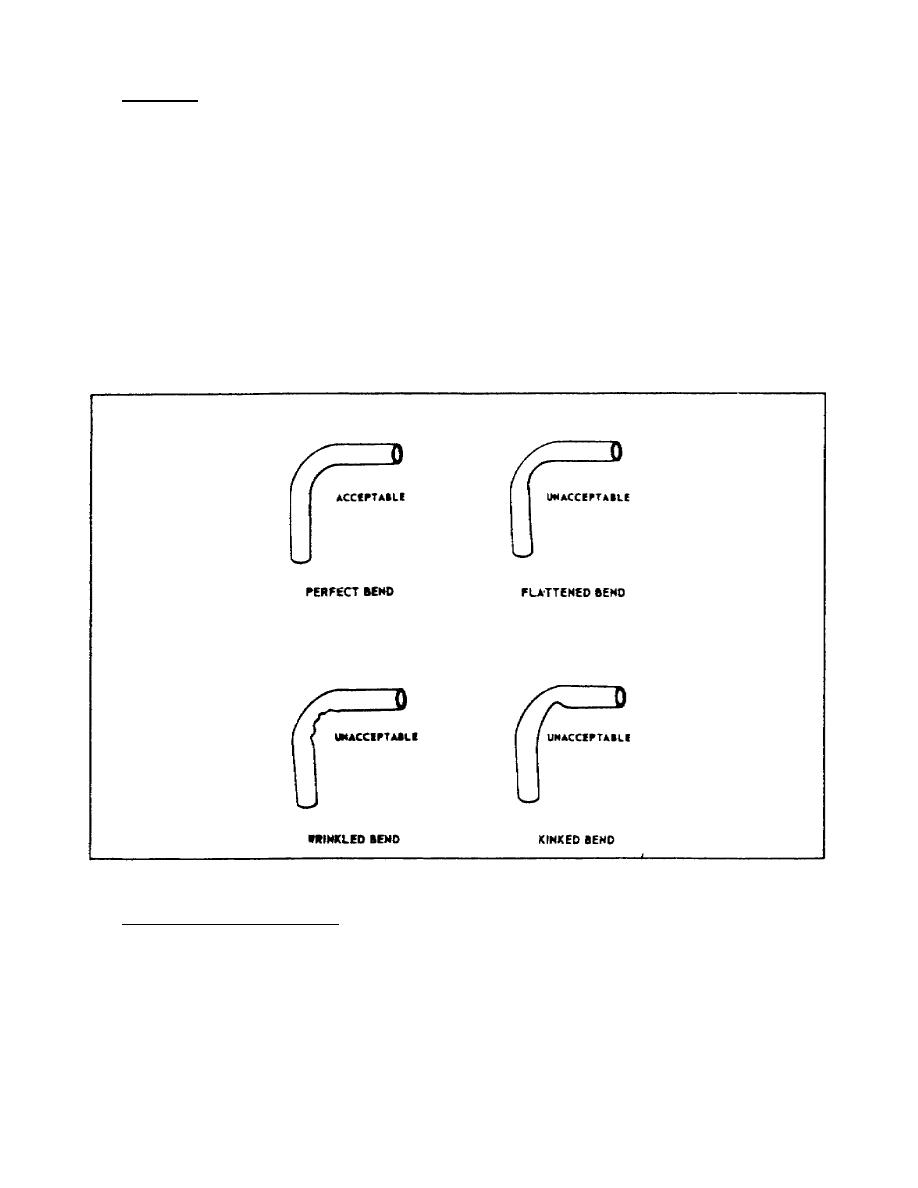

METHODS OF TUBE BENDING

Tube bending can be done with any one of a variety of hand or power

bending tools. Regardless of method used, the object is to obtain a

smooth, even bend without flattening or buckling. Examples of these

results are shown in Figure 2-5.

Figure 2-5.

Acceptable and Unacceptable Tube Bends.

Hand Bending Methods. Tubes less than 1/4-inch in diameter can be

bent with hands, but take care to work the bend gradually. For sizes

larger than 1/4-inch in diameter, use a bending tool; however, this

tool is only effective on thin-walled tubing of soft material.

Two

common bending tools are--

35

AL0907

Previous Page

Previous Page