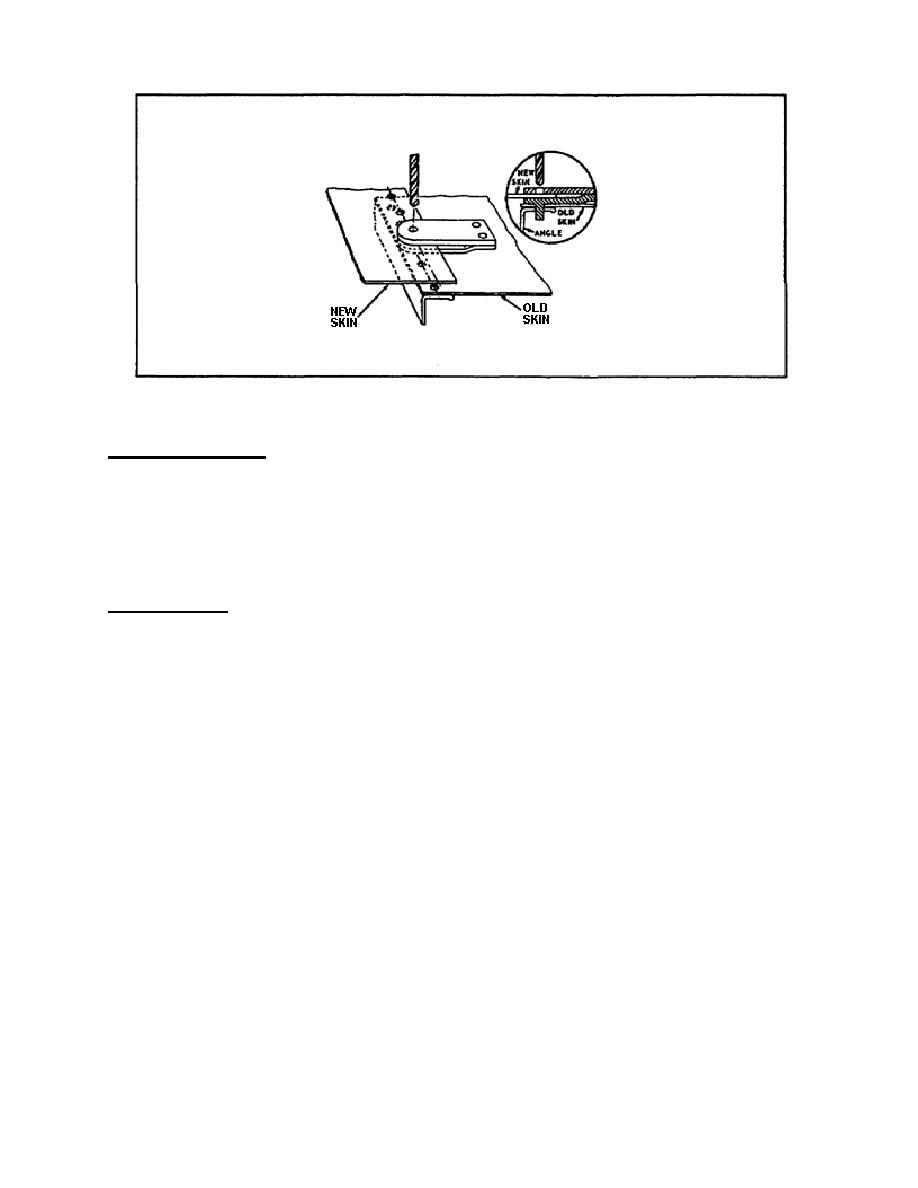

Figure 2-8.

Hole Finder.

Removing Burrs.

The temporary fasteners are taken out and the

sheet is removed from the framework after all the holes are drilled.

Burrs left by drilling must be removed from both sides of all holes

in the skin, stringers, and rib flanges. Deburring can be done with

a few light turns of a countersink drill.

If the burrs are not

removed, the joint may be tight; and the rivets can expand, or flash,

between the parts being riveted.

Bucking Bar. Selecting and using a bucking bar of the correct type

and weight is important to a successful riveting job. For example, a

bucking bar for 1/8-inch rivets must weigh at least 2 pounds. Larger

rivets require proportionately heavier bucking bars.

A light bar

requires too many blows to complete the riveting, and the blows tend

to deform the rivet head.

A straight bar is preferred because its weight can be applied

directly in line with the rivet's shank.

If flanges on ribs or

stringers do not permit using a straight bar, one that allows

straight-line pressure must be used. Figure 2-9 shows two such bars,

(A and B). The bar at (C) or a similar bar can, at best, only create

more damage.

69

AL0992

Previous Page

Previous Page